On Monday, the sink began leaking again. This had been an intermittent problem for some time, so I decided that I was going to fix it. The root of the problem seemed to be a plastic nut that didn’t quite fit far enough on to the threads on the sink to ensure a tight seal. So I hit up the local Ace hardware and purchased a replacement piece. Upon my return, I realized that the solution was in fact a bit more complex that I originally imagined: The new piece I had purchased, while mating beautifully to the sink, could not slip over the plastic pipe due to a secondary pipe that connected into the drain (more on this later). So, it was back to the hardware store again, this time with Enpei and a helpful clerk just before closing, to get an entire replacement dish washer air vent/sink drain mating assembly. After some struggles to find out how everything fir together, we finally got everything figured out, cut down to size, and installed. The best part was that everything seemed nice and tight, especially the connection to the sink. It was a nice chance to apply some latent plumbing skills in the real world. I’m glad its not my job though.

Of course, if that is where it ended, there wouldn’t be an epic adventure. Yesterday, there was water under the sink again. I found out that the left pipe was a little lose, so I tightened it up. However, this simple act got me on a roll and I started fixing things around the kitchen. One problem we’ve had is that we have too many pots and pans to fit into our cabinets. So Enpei, Bobby and I selected the best and most useful subset and put the rest into storage. After moving a few other things around, the place was looking a lot nicer. In fact, with all the extra space, the dishwasher had enough room to actually run it instead of just using it as a drying rack. So we decided to run the dishwasher.

Whoops.

About 1/3 through the cycle, the machine started leaking water at an alarming rate. Fortunately, Bobby and I were still in the kitchen talking, so we caught it early and stopped the machine immediately. We then opened it up to investigate. There was a rather deep pool of standing water that had overflowed the bottom part of the dishwasher. We figured that since the dishwasher hasn’t run in a while, that something must have gotten stuck in the drain. So, we went to work to empty the water out and take a look at the drain. First we used big bowls, then cups, to empty the water out.

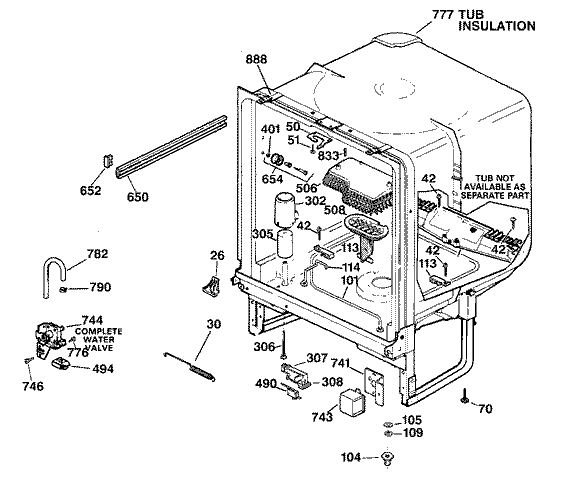

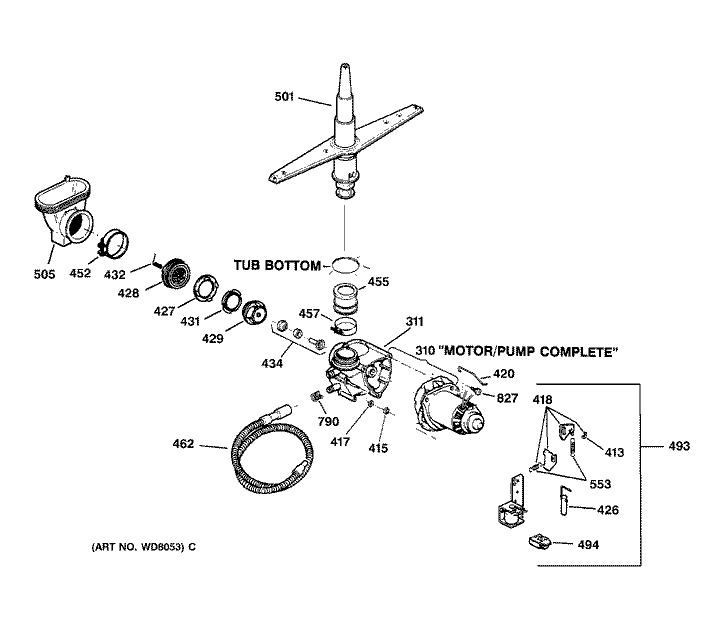

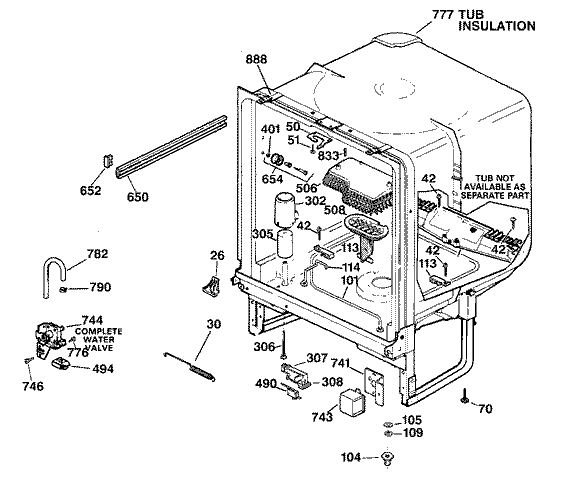

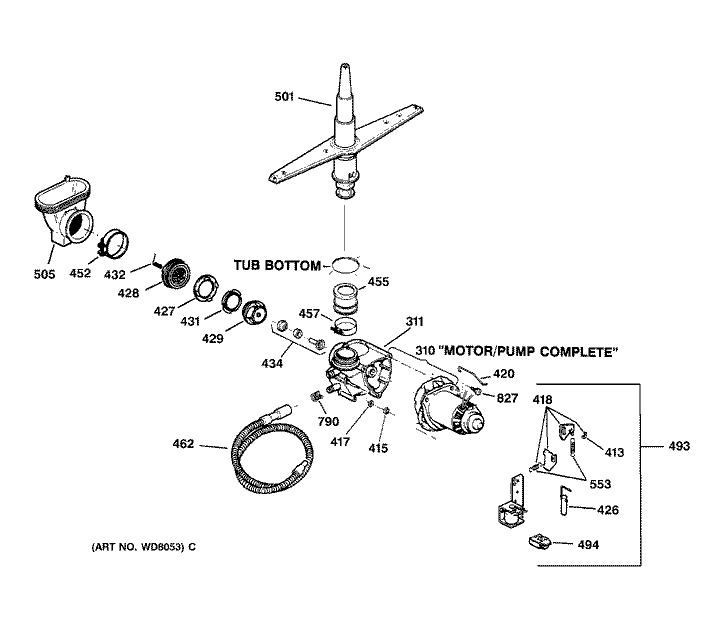

At this point it may be useful to refer to the following diagram:

We saw that the outermost screen (506) was clean, so we took it off (two hard-to-turn screws), and then saw that the inner screen (508) was also clear. Curious, we took that off too, only to find a small, lower pool (505) with another screen that did not lend itself to removal (428). However, even this screen was free of debris (although we did clear out a pop-can tab).

Since it didn’t seem to be related to things stuck on the screens, we decided to try to clear the drain next. Unawares of exactly how the drain system worked, we first thought about a snake (but couldn’t find how to feed it in to the proper tube), and then next thought of Liquid Plumr. We let it sit for 30 minutes but it didn’t go anywhere, and our clog theory was quickly losing credibility. For your information, Liquid Plumbr in a dishwasher is a bad idea. As it turns out, Liquid Plumr is very sudsy. Thick, never-ending sudsy. We had to scoop out many suds. And after that, we had to scoop out more suds. The smell of Sodium Hypochlorate flooded the kitchen. And it was 2:00 am. Again, it was clear that the Liquid Plumr had been a bad idea.

At some point in the middle of all this excitement, I decided that it might be a good idea to watch what the dishwasher was doing, as in with the door open. It was fairly easy to convince the switch that the door was closed and turn the locking lever, which allowed the system to start up. It turns out thatat the beginning of the cycle, the pump pushes a large amount of water quickly through the system. Liquid Plumr-infused water spat up from the belly of the machine and sprayed into the kitchen. I quickly deactivated the machine, a little bit sad that I hadn’t filmed the excitement, but glad that no toxic water droplets had entered my eyes or mouth. This, as it turns out, was another bad idea — but not as bad as the original Liquid Plumr idea.

Stumped, we decided to re-evaluate the source of the problem. The next thing we contemplated was the odd looking plastic nub at the front left of the dishwasher (302). This had a single short screw that was easy to remove. Initially, I thought that maybe the contraption was an emergency drain, but after taking the two plastic covers off, it became apparent that the inner plastic piece was in fact a float that actuated a switch (306) on a post protruding from the dishwasher tub.

In the meantime, Bobby had found the GE dishwasher website from which the above pictures came, and confirmed that the mechanism was in fact a water-float system. We also discovered that what we thought was a drain was in fact the beginning of the motor assembly (505). Apparently — and what a good idea this is — the system reuses most of its water. It just sprays it around over and over, only occasionally actuating a solenoid (assembly 493) that shovels the water out of the drain. Ah-hah! Our new theory was that it must be either the drain tube (462) that was clogged or the solenoid that was not working.

We discovered, somewhat to our surprise, that the drain tube — the only way to get water out of the dishwasher — snaked all the way up to the top of the sink. From our first applied plumbing lesson, I knew that this tube was connected to the dishwasher, but the assembly had said “air vent” as opposed to “dishwasher drain,” so naturally I assumed that the dishwasher had its own big drain underneath, something like a toilet. Well, it turns out that this little tube is the only drain that a dishwasher has! So, forgetting for a moment about the float, we detached the tube from the air vent and ran the snake into it from that direction. We made it easily all the way to the solenoid area at the dishwasher, so it wasn’t the drain pipe that was clogged either. Next, we set about eliminating the solenoid. Of course, we neglected replacing the drain tube back to the drain, so in our test (where the solenoid worked just fine, thank you very much!) we ended up spewing toxic Liquid Plumr hot water all over the area under the sink. Well, having flooded two times in the last three days, it was nothing we were unable to handle, but at 2:00 am it did make us feel a little stupid.

Finally convinced that it wasn’t a clog, and since the original problem was water getting too high and flooding, we finally turned our thoughts back to the (now disassembled) flotation switch. In fact, by leaving the float off, we had been signaling to the dishwasher that it was always full of water, so when we ran the cycle, the solenoid worked fine and the dishwasher drained. So after running a few short test-cycles and determining that the washer was in fact draining, we put the assembly back together, making sure that nothing was jammed, so that the float would work properly. We ran a full cycle and it worked great, completely cleaning itself of all Liquid Plumr residue. So, Bobby having begged off to sleep, I finally put the dishes back in to the dishwasher and started another cycle. As I wrote this post this morning, I checked the dishwasher a few more times to ensure that it wasn’t overflowing. Everything seemed fine and I was dead tired, so I stopped writing and drifted off to sleep.

Its not like I really wanted to do homework last night anyway!